VRIECO-NAUTA MIXER® Conical Screw Mixers

Vrieco-Nauta® mixers offer many benefits including low power consumption, short mixing time, a high level of mixing accuracy, residual-free emptying, and no separation, not even during discharge. Homogeneous mixing and optimum reproducibility of powders, granulates, and pastes is guaranteed for both large and small quantities. Uniform product quality is insured, even under partially filled conditions. These features make the mixers especially suitable for a wide range of processing activities, such as liquid addition, granulation, drying, and cooling. This means considerable savings in terms of labor, investment, and space.

Vrieco-Nauta® mixers offer many benefits including low power consumption, short mixing time, a high level of mixing accuracy, residual-free emptying, and no separation, not even during discharge. Homogeneous mixing and optimum reproducibility of powders, granulates, and pastes is guaranteed for both large and small quantities. Uniform product quality is insured, even under partially filled conditions. These features make the mixers especially suitable for a wide range of processing activities, such as liquid addition, granulation, drying, and cooling. This means considerable savings in terms of labor, investment, and space.

The intensifier is an accessory specially designed to prevent agglomeration when mixing cohesive materials and also for adding of liquids. The conical mixer is centrally fitted with a rapid-rotating rotor, and the intensifier is driven via a separate motor located on top of the mixer's main drive. Various rotors can be fitted, and the rotational speed can be altered to meet the demands of the process.

Extremely large capacity units of up to 1,500 cubic feet or higher have successfully been employed for live storage and "master batching" process requirements.

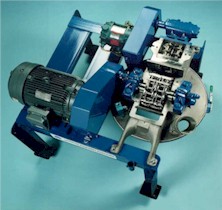

Mikro-Pulverizer® Hammer Mills

The Mikro-Pulverizer® Hammer Mill is a high speed hammer mill designed for uninterrupted production even under severe conditions. Particle size reduction is achieved by impact between the rotating hammers, the particles and a deflector liner mounted in the mill housing cover. This high efficiency multi-purpose mill is also suitable for drying and cryogenic grinding.

The Mikro-Pulverizer® Hammer Mill is a high speed hammer mill designed for uninterrupted production even under severe conditions. Particle size reduction is achieved by impact between the rotating hammers, the particles and a deflector liner mounted in the mill housing cover. This high efficiency multi-purpose mill is also suitable for drying and cryogenic grinding.

The material can be fed by infinitely variable feed screws, pneumatic feeding and gravity feeding. A wide range of products e.g. carbon black, pigments, chemicals, plant protective, colors, dyestuffs, resins, sugar, cacao, paracetamol can be handled.

Most Mikro-Pulverizer® Hammer Mills can operate as a complete stand alone grinding plant. These high-efficiency multi-purpose mills are designed for the size reduction of soft to medium-hard products and are available in sizes ranging from 1- 110 kW in different performing and materials.

Hosokawa Micron Powder Characteristics Tester PT-R

The Powder Characteristics Tester, Model PT-R, is a single instrument which provides seven mechanical measurements and three supporting measurements of dry bulk powders. It complies with Standard Test Method ASTM D6393-99 "Bulk Solids Characterization by CARR Indices". It has been developed to improve handling, efficiency, and accuracy in testing the bulk properties of dry powders.

The Powder Characteristics Tester, Model PT-R, is a single instrument which provides seven mechanical measurements and three supporting measurements of dry bulk powders. It complies with Standard Test Method ASTM D6393-99 "Bulk Solids Characterization by CARR Indices". It has been developed to improve handling, efficiency, and accuracy in testing the bulk properties of dry powders.

The primary functions of the PT-R device are to provide: measurements in a single convenient unit; an additional basis of data for quality control of powdered products; and numerical evaluations of flowability and floodability of powders. The Powder Characteristics Tester features a microcomputer, electronic balance, a data printer, and a built-in dust collection system.

Bulk materials have inherent properties including particle size distribution, bulk density, particle shape, surface area, moisture content, cohesiveness, hygroscopicity, etc. Especially important is the flow behavior (flowability) and the flood behavior (floodability), of powders during production and in their respective application uses.

Developed by: JAMIR Design™

This site has been developed using 1024x768 Screen Resolution and Best Viewed in 1152x864.

This site visited: Times.